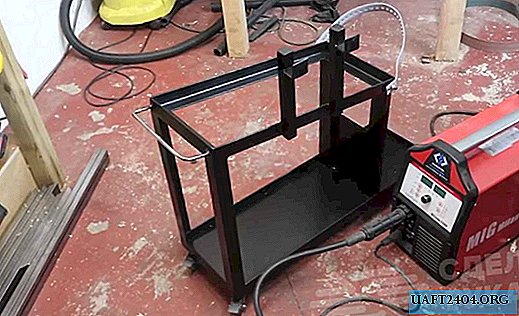

Moving the semi-automatic welding machine together with the cylinder manually is long and inconvenient. Therefore, it makes sense to make a cart with shelves.

For the manufacture of such a cart, pieces of corner and a sheet of metal will be required. You will also need to purchase furniture wheels.

First of all, it is necessary to "take measurements" from the welding machine, after which we cut off pieces of the building corner of the desired size.

The main stages of work

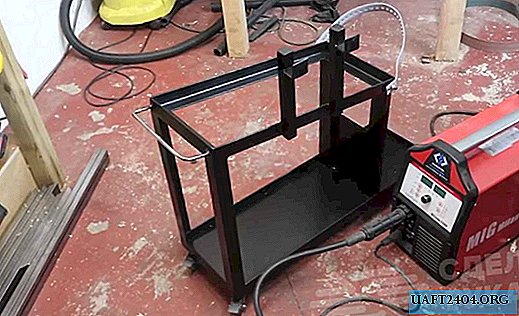

At the next stage, two rectangular frames must be welded from the cut sections of the corner. One is smaller, the other is bigger.

The master welds a sheet of metal to the bottom of the large frame. The optimum thickness is 3-4 mm.

After that, we connect the large and small frames using racks from the same building corner (or you can use a profile pipe). We clean the welds with a grinder.

Using a partition made of a metal plate, the author divides the internal space into two zones: separately for the welding machine and cylinder.

Further, in the upper part of the frame, it is necessary to weld a handle from a round bar, and castors to the bottom.

After this, it remains only to weld two fasteners for the semiautomatic burner. Now you can start painting.

For more information on how to make a cart for a welding machine and a cylinder with your own hands, see the video on our website.