Very often, an old file is used as a blank for a knife, but it is made of specific steel, which although it is hard, but still quite fragile, and under certain loads, such a tool can simply break.

In this case, the author decided to conduct a kind of experiment - to combine with each other two types of metals of different degrees of hardness.

This method of manufacturing the torch will make a really strong cutting tool, and the material will be a broken file and a piece of ordinary metal.

The main stages of work

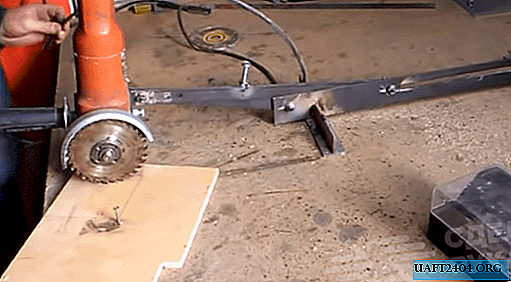

A small piece is cut from the old broken file using a grinder, which will subsequently be the cutting edge of the new cutter. It needs to be welded to a workpiece of ordinary metal, for which welding seams are applied from 2 sides.

The grinder and grinding disc give the workpiece the final geometry, after which the welds are cleaned.

The “stinger” of the file cutter is quenched using a torch. But specifically in this case, the author uses not a gas, but an argon burner.

Draft and then final sharpening is carried out. The product is tested on a glass surface and on hardwood: the cutter, unlike a kitchen knife, leaves deep furrows on the first material and removes fine chips from the second.

Due to the correct combination of two types of steel, this homemade cutter will withstand any, including side, loads. For details on how to make a wood cutter with your own hands, see the video on the site.