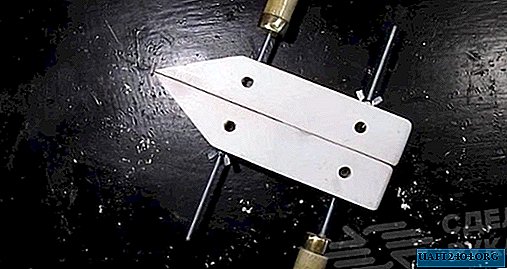

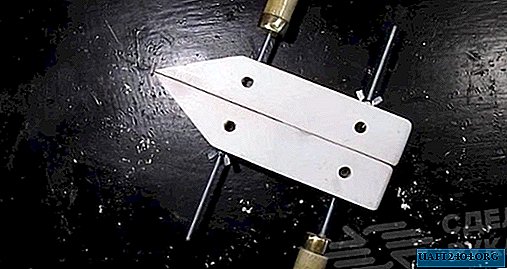

This device is useful to all masters who are engaged in the processing of various parts and blanks. Using a parallel clamp, you can fix the bars, boards and other wooden workpieces at the right angle.

Thus, the part will hold tight in the required position. You can forget that you had to drill on your hands before, because you can use a parallel clamp made of affordable and budget materials. Make it not as difficult as it might seem at first.

How to make a simple parallel clamp from two bars

To make the foundation, it is necessary to divide the beam into two parts. Further, two through holes are made in each half. Their diameter depends on the stud that will pass through them. One side of each bar must be cut off at an angle. On a lathe, the master makes pens.

To prevent the pin from turning in the handle, you need to sharpen the edge in the form of a “tip” of a screwdriver. The blank itself should be completely painted, but the clamping part does not need to be touched. In the holes that are in two bars (clamping jaws), barrel nuts should be installed.

If there are no barrel nuts at hand, they can be made independently from elongated nuts: for this, a hole is drilled on the side and a thread is cut. Next, nuts 25 cm long are inserted into the nuts. On the other hand, their ends are fixed with wing nuts.

Why is it worth doing this design?

Firstly, this handy device is very easy to make. It will always help with the processing and creation of various parts. Secondly, he will not have to spend a lot of effort and money, which is an undoubted plus for any home master.

This homemade product will last for a long time, if everything is done correctly, and does not require the replacement of any elements over a long period of time. A more detailed process of manufacturing a simple parallel clamp you can see in the video on the site.