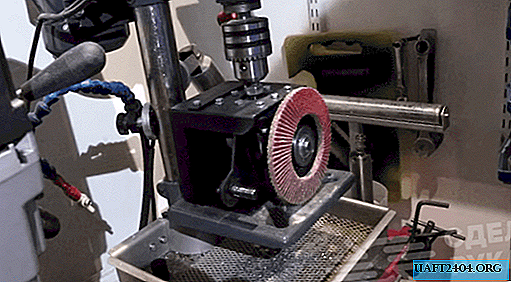

If the home workshop does not have a belt grinding machine (and there is no engine to do it yourself) - it does not matter! Temporarily, you can get by with an alternative option - a home-made tape grinder (electric file), made on the basis of a small grinder.

Using this tool you can:

- remove burrs, rust, excess material after casting;

- grind metal and wood surfaces;

- to clean welds, as well as perform other operations.

Moreover, the design of this device, if desired, can be made universal, with the possibility of using manual and stationary operating modes. In the first case, the angle grinder is held in hands, and in the second, it is firmly fixed in a vice on a table.

The main stages of work

First you need to make a fastener (like a regular clamp), which will be fixed on the gear housing of the grinder. This will require a rectangular metal plate 2-3 cm thick.

We drill a hole in it with the help of a crown, and then we finish using a grinder with a cutting disc and a grinding machine. In the end, you should get such a detail.

On the lathe, it will be necessary to make a drive roller, which is worn on the gear shaft of an angle grinder. On the outer surface, you need to make small notches so that when the tape grinder is working, sandpaper does not slip.

Then a driven roller is made of six bearings, an adjustable bracket with two telescopic tubes.

At the last stage of work, we assemble the belt grinder from the grinder. For a detailed process of making a home-made electric file, see this video.