A small machine for grinding products and workpieces made of metal and wood is useful both in the workshop and in the garage, and in the country (for example, to round the edges of cuttings or to sharpen knives and garden tools).

If you do not plan to use the grinding machine constantly, then buying a factory-made model does not make sense. In this case, it is easier and cheaper to make a homemade version from improvised materials.

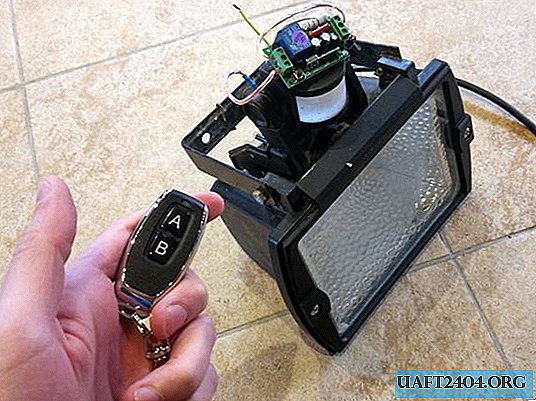

The main components of the structure are made of wood, standard fasteners (bolts with nuts, as well as self-tapping screws) are used for connection. An ordinary household electric drill acts as a drive.

Grinding machine manufacturing process

First of all, from a piece of plywood or a board of suitable sizes, you need to cut out the base on which the details of the grinding machine and the electric drill will be located. Then we collect the lower part of the structure.

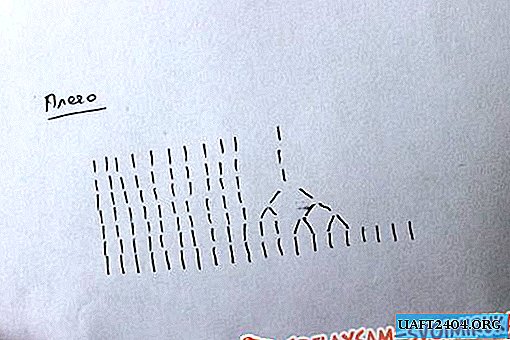

To do this, we wind two rollers cut from wood or plywood onto a long bolt, and then insert the bolt into a wooden square, into which the bearing is pressed. On the reverse side we squeeze well with a nut.

Now we proceed to the assembly of the upper part of the vertical grinding machine. A wooden stand with a “shoulder” is mounted on the base, to which a second roller is mounted - a tension one.

A piece of board with a bolt is screwed to the top to adjust the degree of tension of the sanding belt. It is also necessary to place the linings under the electric drill on the base, and then fix the tool with clamps. The result is a simple design of a grinding machine for home use.