Very often, in the process of manufacturing various homemade products from wood or welding metal structures, it is necessary to connect workpieces at an angle of 90 degrees. And for this, we recommend making a very simple but useful tool that will help you do the job quickly and efficiently.

Work stages

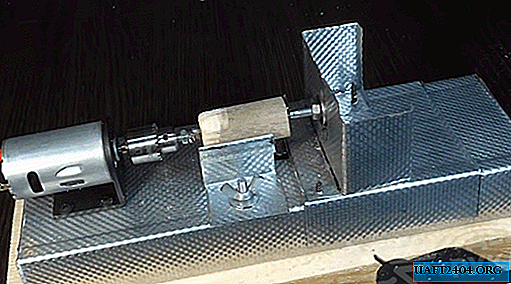

We cut off two identical pieces of 20 cm long from a 40 mm wide metal strip with a grinder. A washer is welded on one side of each workpiece (so that it is vertical). We clean the places of welds from slag and process them with a stripping disk. Then we connect two strips with a bolt and a wing nut.

At the next stage, we cut two identical pieces of a steel corner 60x20 mm, drill one hole in them, clamp in a vice and weld ordinary hex nuts to the holes. Next, we install the corners with nuts on the sides of the plates and fix by welding. The seams must be cleaned with a grinder.

We screw the studs into the holes in the corners through the nuts. Short pieces of round timber are welded to the studs to make it more convenient to twist them. Then we disassemble the structure, grind it if necessary and cover it with a layer of quick-drying spray paint from a spray can. After the paint dries, we collect everything back.

To summarize

The result is a very convenient, compact and practical hand tool that is useful to every master. Using this device, various wooden and metal workpieces can be joined at right angles (for example, for drilling holes or welding). See the step-by-step process of manufacturing the tool in the video on the site.