Homemade devices that are used to cut bottles, as well as other glass containers and vessels, are most often made on the basis of a conventional glass cutter. However, such devices are quite primitive and do not always cope with the task assigned to them.

A more "advanced" version of the bottle cutter works a little differently - it cuts glass by heating with a hot nichrome thread. In this case, it is possible to achieve a sharper and more even cut than when using devices made on the basis of glass cutter.

The main stages of work

A transformer from a matrix printer is used as a power source along with a control board - it contains a switch, power filters and a fuse. It is desirable that the fuse be 3 A. If the circuit board has a weaker fuse (1 A or 2 A), then it must be re-soldered.

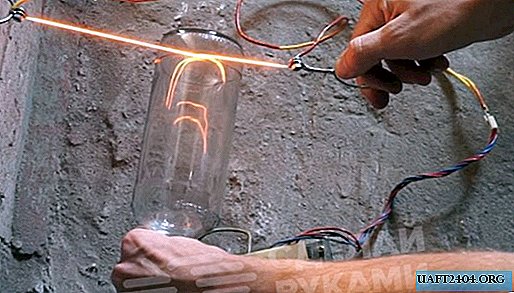

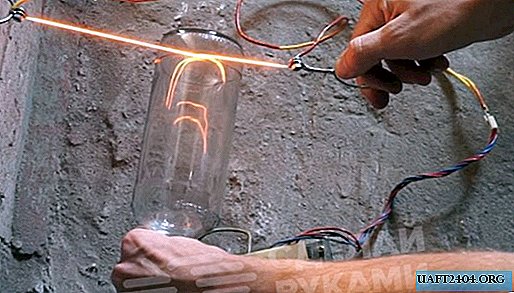

To make it easier to cut the bottle, the nichrome thread must be connected using metal rings. One ring is fixed, for example, by a nail in the wall or another ledge, and the second must be pulled. To align a nichrome thread, it needs to be heated and slightly pulled. After cooling, the wire will not twist into turns.

Bottle cutter at work

A single wire will burn out, so it’s better to immediately twist the double in the form of a spiral. We make one turn around the bottle, turn on the transformer, pull the thread and hold for a few seconds. Quickly remove the wire and cool the place of "cauterization" with water. As a result, the bottle is cut perfectly and practically without chips.